eKanban

Always know exactly which part has which stock. eKanban solutions from ekko enable a reduction in inventories while ensuring high, consistent material availability.

In operation at a large technology group.

Before ekko:

Before the introduction of ekko eKanban, materials management was a laborious and error-prone process. Employees had to manually monitor stock and replenish containers, which was not only time-consuming but also led to frequent errors and delays. Manual monitoring and reordering was inefficient and led to bottlenecks in the production process. In addition, accurate inventory tracking was a challenge as there were no automated systems in place to monitor the flow of materials.

With ekko:

The eKanban system from ekko has drastically improved material management. The automatic detection of empty bins and seamless reordering has saved time and reduced errors. Employees can now concentrate on their actual tasks instead of being burdened with manual ordering and monitoring tasks. In addition, not only has efficiency been increased, but the quality of processes has also been improved and overall performance optimized.

The unique aspects of the ekko eKanban system

The ekko eKanban system controls material management through intelligent automation and precise stock monitoring. As soon as a container becomes empty, the ekko platform automatically recognizes this and immediately triggers a reorder. The removal of material is simplified by acknowledgement on the ePaper display, which automatically adjusts the stock. The replenishment process is triggered seamlessly with individually defined threshold values.

In addition to automatic detection, reorders can also be triggered manually at the touch of a button or even by scales. ekko enables comprehensive monitoring of stocks and the adaptation and optimization of processes for maximum output with maximum efficiency. With the ekko eKanban workflow, companies can achieve time savings of up to 40%.

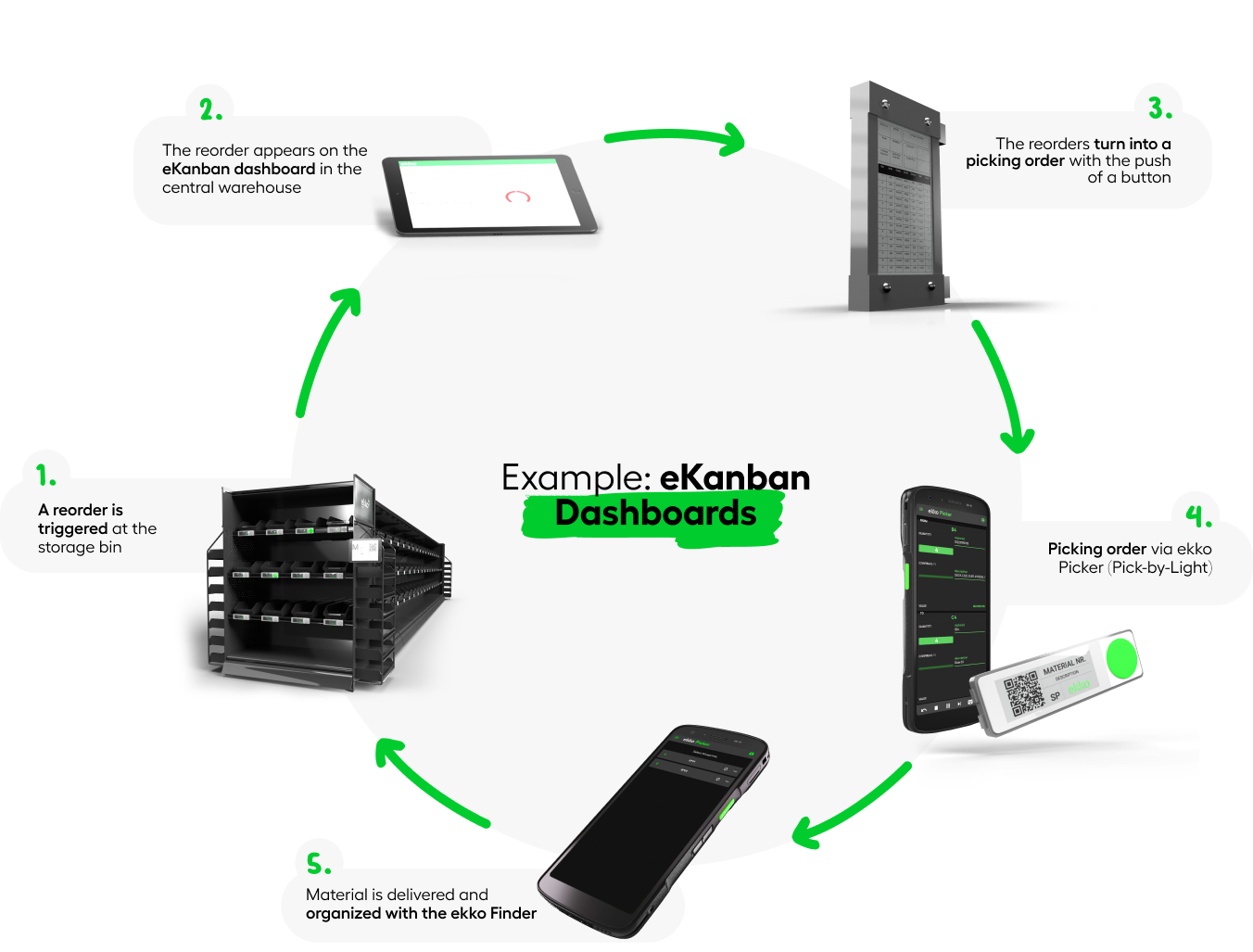

How does the ekko eKanban workflow work?

Free Brochure

✔️ Technical possibilities with ekko

✔️ Examples of our customer

✔️ Detailed ROI calculations